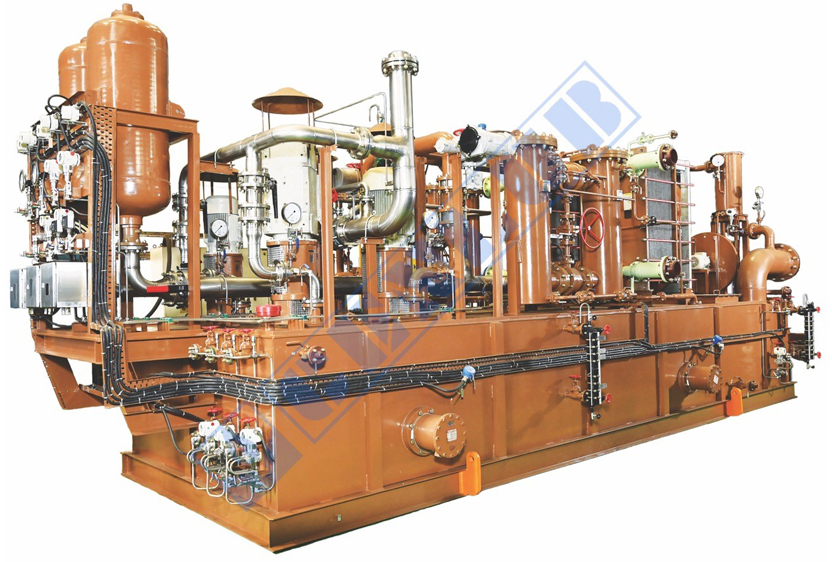

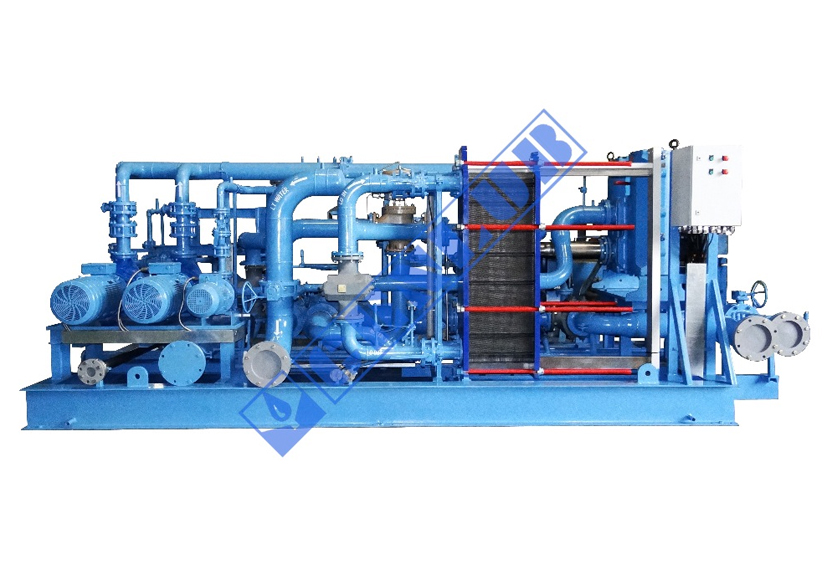

API 614 in India

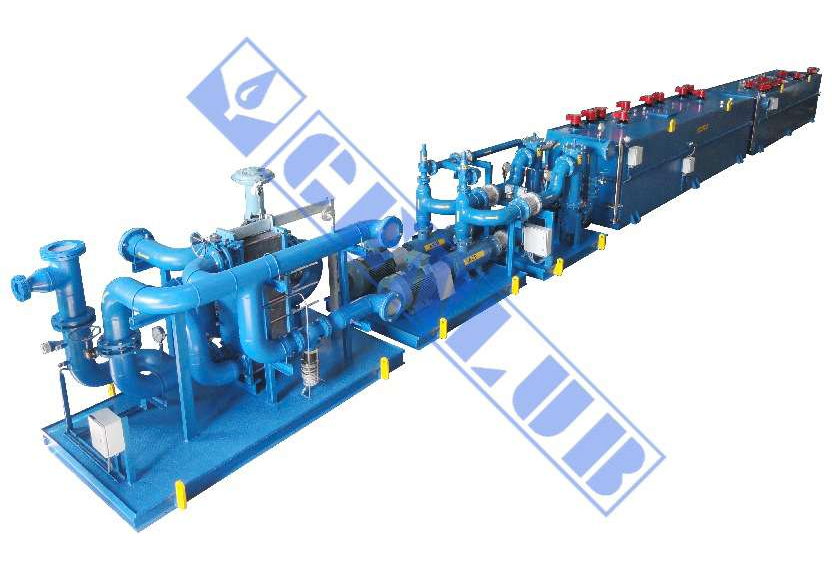

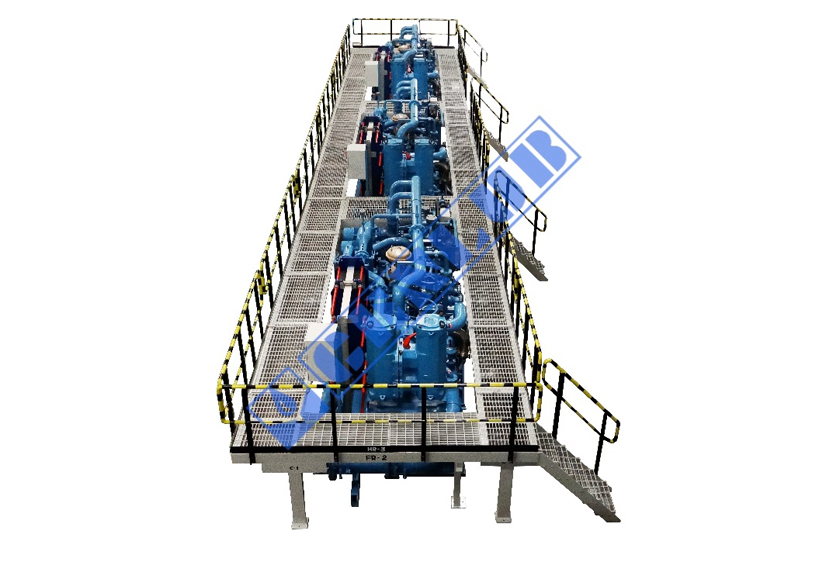

API 614 in Saudi Arabia

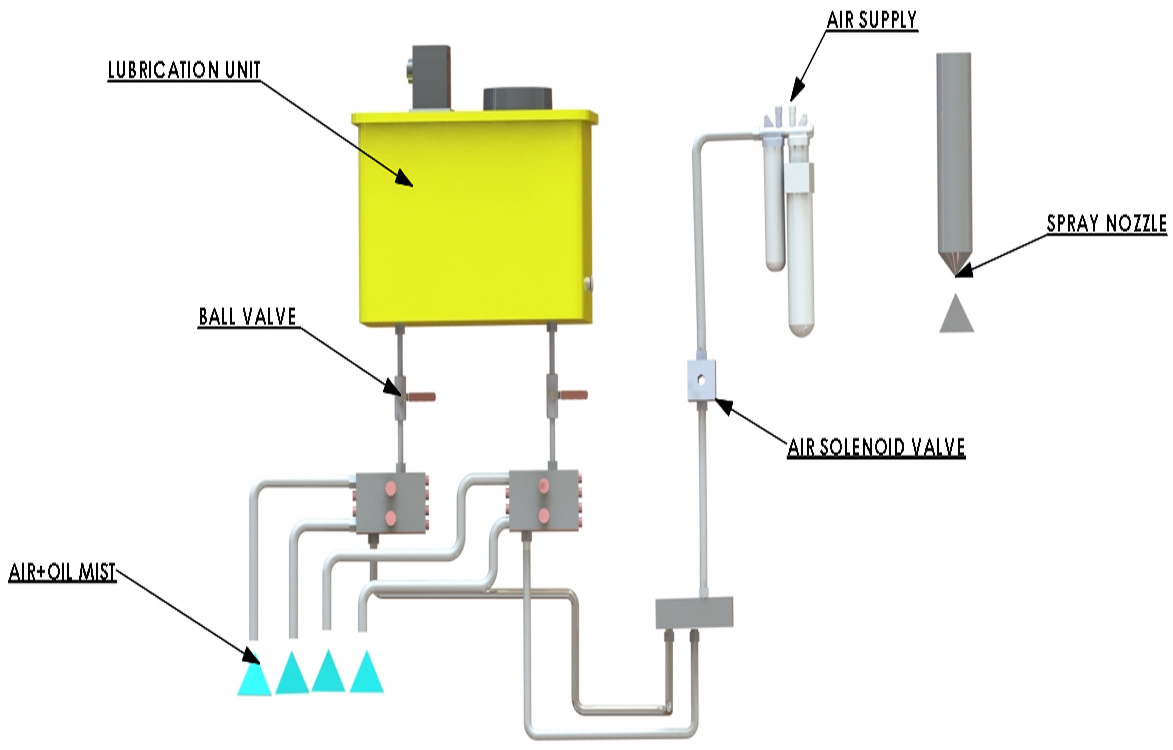

The Air oil spray lubrication system is a versatile solution widely applied across diverse industrial settings where precise and efficient lubrication is essential. It finds use in various applications, including metalworking machinery, automotive manufacturing, textile industry, printing presses, and food processing equipment.

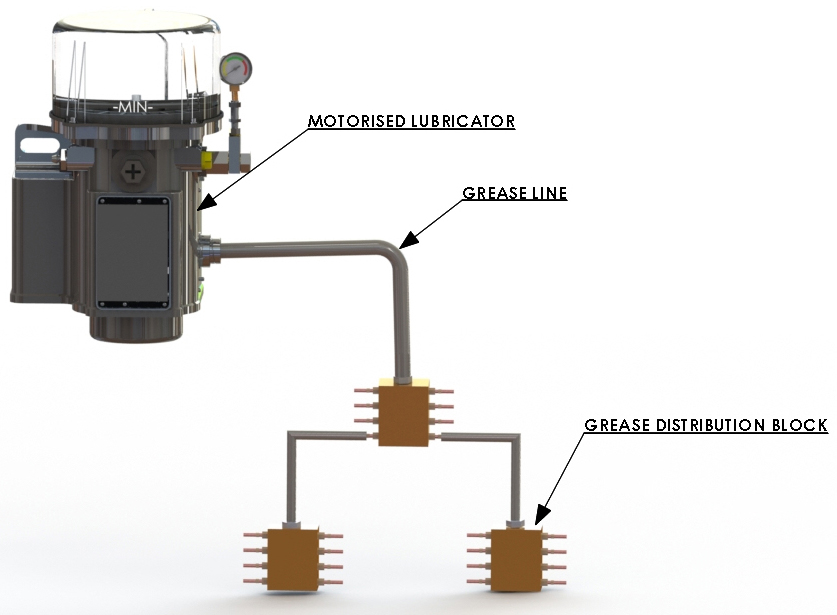

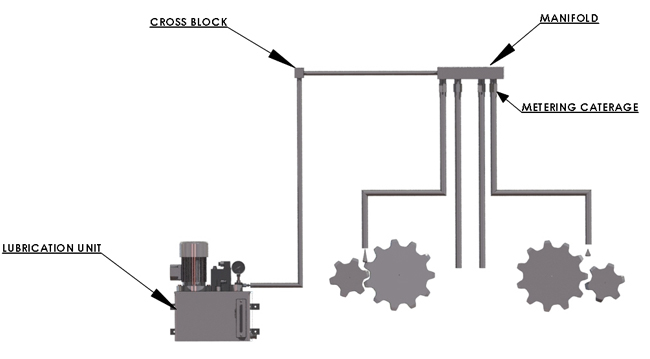

The operation of the system involves several key components and processes. Firstly, lubricating oil is stored in a reservoir and supplied to spray nozzles through a network of pipes. Compressed air, sourced from an air compressor, is mixed with the oil in a chamber or manifold, where the oil is atomized into fine droplets. These droplets are then sprayed onto lubrication points using precision-engineered spray nozzles, which can adjust the spray pattern and volume as needed.

A control system, often comprised of a control panel or programmable logic controller (PLC), regulates the operation of the air and oil supply, timing of lubrication cycles, and monitoring of system parameters. Lubrication cycles are determined based on equipment requirements and operating conditions, with the system delivering a precise amount of lubricating oil to lubrication points during each cycle.

Additionally, the system may include sensors or indicators to monitor oil levels, air pressure, and overall system performance. Regular maintenance, such as oil replenishment and nozzle cleaning, is crucial to ensure the system’s proper operation and longevity.

It is best suited for :

High speed anti-friction Bearing Lubrication.

Lubrication of Gear Trains,

Small pitch Conveyor Chains.

| Technical Specifications | |

|---|---|

| Pump delivery | Between 3 mm3 and 30 mm 3 in minimum increment of 0.7 mm3 . |

| Number of pumps | 1 to 6 |

| Cycle frequency | 3 cycles/second to 1 cycle/min. |

| Tank | 0.4 L, 1.2 L, 3 L & 6 L |

| Material of tank | Transparent thermoplastic |

| Power Supply | 230 V /110 V AC, 50/60 Hz / 24 V DC, 24 V 50/60 Hz. |

| Lubricant | Mineral, synthetic and vegetable oils. |