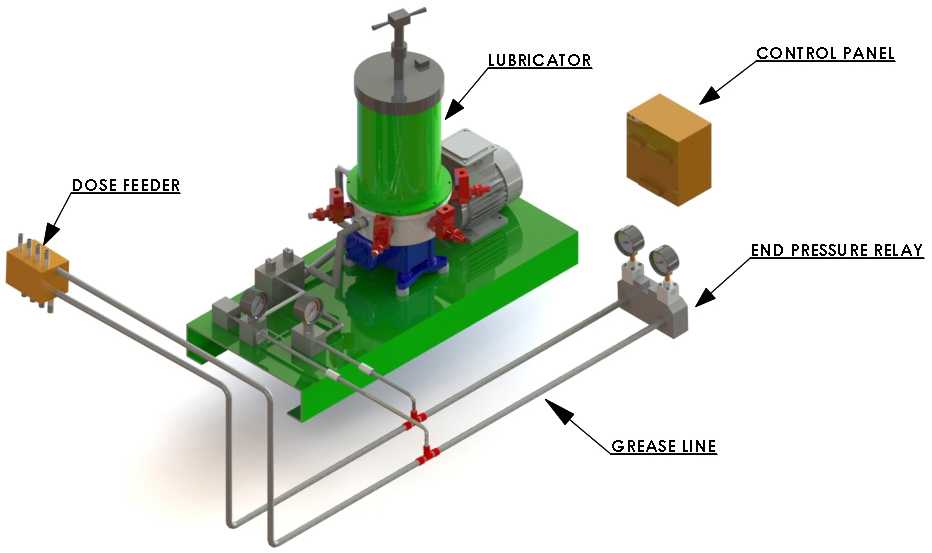

Dual Line Grease Lubrication System

A Dual Line Grease Lubrication System is a sophisticated method used to deliver grease to multiple lubrication points within industrial machinery. It operates on a dual-line principle, where grease flow is alternated between two main lines. This ensures consistent and reliable lubrication across various components of the mac.

| TECHNICAL SPECIFICATIONS | ||||

| Model | DLGP-50 | DLGP-70 | DLGP-100 | DLGP-140 |

| Reservoir Capacity (Kg) | 50 | 70 | 100 | 140 |

| Lubricant (Grease) upto Grade NLGI | II | II | II | II |

| Max. Discharge Capacity (in gm/mt) | 150/300 Min/Max | 150/300 Min/Max | 150/300 Min/Max | 150/300 Min/Max |

| Max. Discharge Pressure in (kg/cm²) | 250 | 250 | 250 | 250 |

Dual Line Grease Lubrication System Accessories

Dose Feeders

The dose feeder accurately dispenses grease to each lubrication point, preventing both excessive lubrication that can cause messy build up and insufficient lubrication leading to wear and tear. It ensures optimal performance by precisely metering the grease flow to match the machinery’s requirements.

Specifications:

- Discharge 0.5-2.0 gm/cycle : DLDF41

- Discharge 1.5-5 gm/cycle : DLDF42

- Outlet : 4

Hydraulic Over Pressure Reversing Valve (For Loop Type)

This valve alternates grease flow between two main lines in the system, ensuring that each lubrication point receives grease consistently. By controlling the direction of the flow, it helps maintain balanced lubrication across the machinery, reducing friction and extending component lifespan.

Electrical Change Over Valve (For End Type)

Operating electronically, this valve switches grease flow between lines based on signals from the control unit. It enables automated and synchronized lubrication cycles, enhancing efficiency and reducing the need for manual intervention. This precise control ensures that each lubrication point receives the right amount of grease at the right time.

Filter

Filters installed in the system remove contaminants from the grease, such as dirt and metal particles, preventing them from reaching critical machinery components. By keeping the grease clean, filters reduce the risk of blockages in the lubrication lines and minimize wear on machine parts, ultimately prolonging the system’s lifespan and enhancing Application in Steel Plant, Sugar Plant, Cement Plant, Textile etc.

End Pressure Replay

End pressure relay monitors the hydraulic pressure at the end of each lubrication line. When the pressure reaches a predetermined threshold, indicating that the lubrication cycle is complete and all lubrication points have received grease, the relay sends a signal to the control unit to stop the lubrication process. This helps prevent over-lubrication and ensures efficient use of grease, ultimately contributing to the optimal functioning of the machinery and prolonging its lifespan.

Electrical Control Panel

Electrical Control Panel for Dual Line Grease Lubrication System: Specifically designed for dual line grease lubrication systems, this control panel offers centralized management and monitoring of lubrication processes, ensuring optimal performance and equipment longevity.