Lubrication System for Cement Plant

In cement plants, where the machinery operates relentlessly under demanding conditions, the implementation of centralized lubrication systems is paramount. These systems are strategically deployed in Crushers, Mills, Kilns, and Conveyor Systems to ensure uninterrupted operation and minimize downtime. By delivering precise amounts of lubricant to critical components, such as bearings and gears, centralized lubrication systems from Cenlub facilitate smooth operation, reduce friction-induced wear and tear, and extend the lifespan of machinery. Ultimately, the use of centralized lubrication systems in cement plants leads to enhanced operational efficiency, increased productivity, and reduced maintenance costs.

Lubrication Products For Cement Plant

Applications

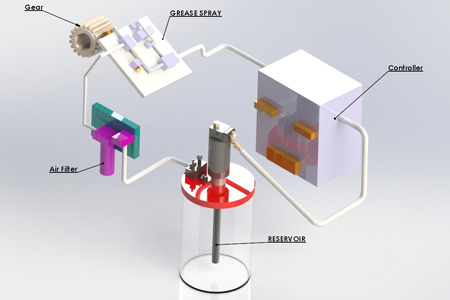

- Consistent and precise lubrication of critical components such as gears, bearings, and slides.

- Reduced friction and wear on machinery, leading to extended equipment lifespan.

- Decreased downtime for maintenance, enhancing operational reliability and productivity.

- Minimization of human error through automated lubrication processes, ensuring uniform lubrication distribution.

- Improved efficiency, reduced maintenance costs, and increased profitability for automation operations.